For Burning Man this summer I made a novel dwelling, sort of a cross between a monkey hut and a hexayurt, in the sense that the design itself is very close to being a monkey hut (a hemicylindrical structure with a flexible skin stretched over a rigid frame) but the structure is fully enclosed and insulated, a complete shelter, rather than just a shade structure for a tent or something. Basically it’s a Quonset hut made of reflective bubble wrap.

Here’s what it looked like right after I set it up.

I was pretty happy with how it turned out, and how well it survived repeated windstorms, and so I thought I would post here about how I made it. This could probably be improved quite a bit, but I’ll try to stick to documenting what I did and leave speculation about what might work better as an exercise for the reader.

The floor of the structure was a white 12’x16′ tarp. Now, an interesting (?) fact about tarps is that the advertised dimensions are almost always larger than the actual dimensions, because the “cut size” is smaller, after rolling up the edges to reinforce them or whatever it is they do, I don’t even know. In this case, I wanted something that was actually 12’x12′ or more, so I got a 12’x16′ tarp that was advertised to be actually 12’x16′. It still wasn’t quite as big as advertised, but close enough for my purposes. Also I got a white tarp because I was tired of having a blue floor, and too lazy to put carpet, and also if you cover up the floor it insulates it from the ground, which actually isn’t so good because the ground maintains a more constant temperature than the air and therefore warms the structure at night and cools it during the day. I mean actually I haven’t tried with a carpet, maybe it would be fine, mostly I’m lazy. Oh, another big advantage of a white tarp is that it’s a lot easier to mark it up with a black sharpie.

During disassembly, after taking down the wall with the door in it.

So! Before heading out to the playa, I stretched out the tarp and put arrows along the long sides. First, four arrows at the corners, a bit less than 12′ apart, centered so that there were roughly equal amounts of extra tarp sticking out on each side (but somewhat less than two feet because it wasn’t a full 16′ long, as mentioned previously). Then between those arrows I put four more arrows, two on each side, at roughly 4′ intervals, for where the inner ribs would go. I wanted the ribs to be almost 4′ apart, rather than the 5′ suggested in the standard monkey hut design, because the rolls of Reflectix bubble wrap I was using are 4′ wide. I’m pretty sure the standard design uses 5′ mostly because you waste less pipe when cutting the pieces for the spine, since PVC pipe is sold in 10′ lengths.

I also put two big Xes on the tarp along the centerline, between the two corners, in the middle of each side wall, for an extra vertical support that the standard monkey hut lacks, because I wanted closed sides instead of open sides.

Floor tarp markings.

Next is the big roof piece. I got a 100’x4′ roll of Reflectix from the Home Depot website, which came in a big box, and I cut three 25′ lengths. In principle 20′ would be enough but I wanted some extra on each end, for reasons that will probably become clear once I get to the bit about the plywood. The extra 5′ was probably more than I needed.

I taped the three 25’x4′ pieces together to make one big 25’x12′ piece, which could be folded accordion-style into a triple-thick 25’x4′ piece which I could then sort of awkwardly roll up into a big cylinder. I taped the two seams with 3′ wide bidirectional filament strapping tape, the kind you use for hexayurts, which I think I bought from the U-LINE web site — it’s a bit hard to find. It’s very strong tape and it sticks well to the Reflectix, much better than trying to tape two polyethylene tarps together. I taped both sides of each seam, and I went over one side of each seam (the side that was going to be outside the structure, exposed to the sun) with some 3′ wide Reflectix aluminum foil tape, again the same kind of thing you’d use for a hexayurt. This is supposed to help keep the tape from breaking down as quickly in the desert sun. Not sure I would bother with the silver tape next time, but I did not regret taping both sides of each seam with the bifilament tape.

Bubble wrap for arched roof/walls.

I should note at this point that taping these big pieces of bubble wrap together was pretty awkward. I needed a big space — the yard outside my apartment was where I ended up doing most of the work, since I don’t have a room indoors that big. Mostly what I would do was to stack up the three panels, one on top of the other, and then tape two of them together along one long edge. I found that it was better to use a bunch of short lengths of tape, no more than a few feet each, and overlap them slightly, rather than trying to use a single unbroken 25′ length of tape, which would inevitably end up getting tangled or applied unevenly and do a worse job. I had to open and flip the panels around to tape both sides, and it was confusing, and at one point I think I taped the wrong pair of panels to each other, which is easy to do, and then if you want to do the aluminum foil tape it’s easy to get confused about which side is the same side as the one you already did.

Taping the three strips of roof together, out in the yard.

Next were the side walls, for the end caps of the half-cylinder. Unfortunately I didn’t quite have enough material left over from the first roll, so I had to get a second one. I decided to make the two side walls different, because I wanted a door in one of them, and for some reason I decided it would be better to have the door in the middle of a panel instead of having a seam down the middle of the door, so I divided the walls into panels in two different ways. One wall was made of three 8’x4′ strips taped together into a single 8’x12′ piece. The other one was four panels — I made 3 8’x4′ panels like the first one, but cut one of the panels into two 8’x2′ pieces, and put one piece on each side, to make an 8’x12′ piece with one of the seams exactly in the middle. I guess I could have just used two 12’x4′ pieces and taped the long sides together to make a 12’x8′ piece, but I wanted all of the seams on the structure to be vertical, because I thought it might be stronger that way, given how it’s all going to be held together. But who knows. I might try it the other way next time. These double-taped seems seem pretty strong.

Bubble wrap for the two flat semicircular walls. The door goes in the middle of one of the two big rectangles in the bottom piece. Er, horizontally in the middle; vertically it’s a bit closer to the bottom.

Um but so anyway. The side pieces are 12′ wide because that’s how wide the structure was going to be… actually the structure itself was a bit less than that, because I wanted a bit of overlap at the seams, and because the tarp was not quite 12′ wide, so 12′ wall pieces were perfect, really barely enough. And 8′ because the overall structure is about 6′ tall, maybe a bit taller if it’s less than 12′ wide, but again I wanted some extra length to work with at the top and bottom to overlap things and to hold things down at the bottom, and in fact 8′ seemed like a pretty good height for those pieces. I taped everything together with the 3′ wide bifilament tape on both sides and an extra layer of silver tape on the outside only, just like for the big roof piece, and folded and rolled them for transport.

The two small wall pieces, loaded for transport.

All this taping took maybe 3 or 4 hours or more in total? Not too bad, but not trivial.

Next was the wood! I bought four 2x4s at Home Depot. As with tarps, a 2×4 isn’t actually 2″x4″, it’s more like 1.5″x3″ or something, because the cut size is smaller… but it doesn’t matter, the point is the length. The ones I got were 12′ lengths, which was perfect except that I can’t fit a 12′ long piece of wood in my car, so I had them cut each piece in half, into two 6′ lengths. If I were doing this again I might try something even a bit smaller and easier to fit, like three 4′ lengths.

Anyway! The point of these pieces of wood is that they are going to go all the way around the edges and act like giant staples, to hold the walls and roof down. You drill holes in the wood ahead of time, put them right on top of the extra foot or three of Reflectix that is sticking out at the bottom, and hammer bent rebar into the holes, right through the bubble wrap and any protruding tarp, to hold everything down nice and tight. I drilled holes at 2′ intervals, offset from the sides of each piece, so each 6′ piece had a hole at the 1′ mark, the 3′ mark, and the 5′ mark.

Wooden “staples.” Notice how the corners work. This lets the wood fit close to the frame even if the dimensions don’t match exactly.

I used a spade bit with a power drill to drill the holes. I’d never used one of those bits before, and it took me a while to figure out how it works. I wondered whether it would be best to drill a pilot hole first, with a normal bit, but after some experimentation I decided that, no, the pilot hole was not helping (and actually made things worse, if I made it too big), and it was easiest to just go straight at the undrilled wood with the spade bit. I think the one I used was 5/8′ or something? At least a little bit bigger than the rebar — you don’t want the rebar to be snug, you want it to be able to fit through the hole very easily, with a little extra space. I got a bit of extra wood from a nearby construction site to put under the 2×4 as I was drilling it, then put my foot on the wood and drilled straight down, right into the scrap wood. The holes were not super clean but they didn’t need to be. This probably took an hour or three, much of which was spent experimenting, but things started to go much faster once I got the hang of it.

I had some pre-bent candy cane shaped rebar stakes that I’ve been using at Burning Man for the past several years, in a mix of 12″ and 18″ lengths, that I originally ordered from some online deer fence place that was selling them as fence stakes to keep deer or dogs or other animals from digging under the fence. Nice clean tight 180 degree bend. I understand that you can also bend the rebar yourself, using steel pipe or something. The bent part just runs straight into the top of the wood and holds it down, rather than going over the edge of the wood and into the ground. If it did stick over the edge, I’d want it to be an outside edge, so as not to make a hole in the structure that would let dust in. Not that it’s going to be completely dust-tight regardless, but every little bit helps.

Assembled PVC pipe skeleton. The curved pieces are the “ribs.”

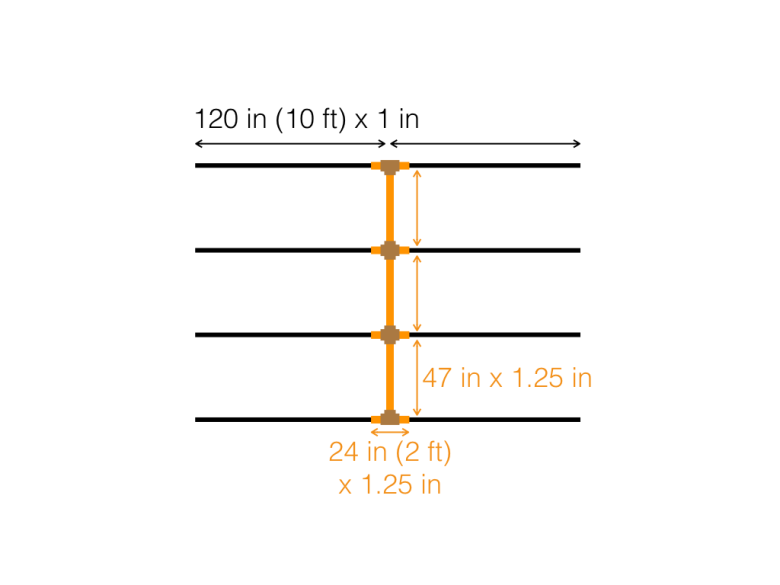

The last big of major preparation is to buy PVC pipes, cut them, and tape them, as described on the monkey hut page with only a few differences. I got 8 lengths of 10’x1″ schedule 40 pipe for ribs, 2 10’x1.25″ pieces for vertical legs (to be cut on-playa), two extra 10’x1″ pieces to slide inside the legs as reinforcement or to serve as spares if anything happened to any of the ribs (this was probably overkill, not sure I’d bother next time), and a few big and small pieces of 1.25″ pipe to make the spine and the rib connectors. Be sure to get schedule 40, not the other kind, or the walls will be the wrong thickness and they won’t nest correctly! There are three spine pieces to go between the four pairs of ribs, nominally about 4′ each but I made them more like 3’10” to account for the width of the connectors — you can measure how much length they add to the spine, it’s not a huge deal but I wanted to make sure that the 12′ wide roof piece would completely cover the spine so I figured I’d rather make the spine a little bit short than have it come out too long, and I did not regret doing this at all. My rib connectors were 2′, not 2.5′, because I bought like three 10′ lengths which wasn’t quite enough to make all the spine pieces and all the rib connectors so I bought like one or two pre-cut 2′ pieces, since Home Depot sells them and I don’t like having too much extra pipe. I could probably also have trimmed down the vertical legs a bit — they needed to be more than 6′ but certainly less than 8′. Anyway.

The 8 long PVC rib pipes, after I disassembled them and cut them in half to make it easier to load the car for the trip home. Which you shouldn’t do, if you plan to reuse them! I am a wasteful person. Anyway. Note the black tape near one end of each (full) pipe.

I put duct tape 1′ from one end of each of the ribs, to get them to slide the right distance in to the 2′ rib connectors, and I wrapped duct tape around both ends of the spine pieces to get them to fit just snugly into the connectors. I also put duct tape around the middle of each rib connector, slid the appropriate connector onto it, and put a little piece of tape inside to keep the connector from sliding off in transit, while still allowing it to move around a bit to make assembly easier and let the structure shift with the wind and all that.

Flattened PVC pipe frame, excluding the two vertical supports.

Forgot to mention connectors! There are only four. Two were regular 4-way crosses, 1.5″ slip-fit, from Home Depot. The other two, which would be 3-way tee connectors for a regular monkey hut (without vertical supports), had to be fancy 4-way connectors that go in three dimensions, which Home Depot doesn’t sell, because you would never need a connector like that in real plumbing — it would be easier to just buy two tee connectors and put them near each other. But there’s a place online that sells “furniture grade” PVC pipe and connectors and has all sorts of exotic connectors with various weird angles that are good for building structures like this, so I picked up the two I needed from there.

What else? Rebar! I already mentioned the candy-cane pieces — one for each hole in the wood, so, uh, 24 of those I think? Plus straight rebar for the ribs and the vertical legs. I always use 2’x3/8″ because those are long enough that the pipe won’t slide off, but they don’t need to actually withstand being pulled out very hard, at least not in this design, so there’s no need to go with anything longer or thicker. Ten of those: one for each rib, and one for each of the two vertical legs.

What else? Furnace filters, to make windows! I used two windows, on opposite sides of the structure, each of which was a 14″x14″x1″ filter bought at Home Depot. I ended up bringing 6 total, so I’d have spares, but I only replaced the windward one once, I think. But then I lent one or two to Mingjing for her yurt, so that was okay.

I also brought several rolls of magnet tape to make a door, like 15′ or more. Honestly I think I would have been better off using a zipper instead. Home Depot sells self-adhesive zippers that are meant to go in the middle of a tarp that I bet would work great, or else I bet there are lots of other places to get double-sided zippers that you could just sew on to the bubble wrap or something. I pre-cut an octagonal door hole in one of the wall panels (3′ tall by 2′ wide rectangle with the corners cut off to make it a bit stronger), and used a scrap piece of bubble wrap to make an oversized octagonal door that was 2″ or 3″ larger than the hole all the way around. I tried attaching the magnet tape to the bubble wrap ahead of time but this didn’t really work out for me and I had to re-do it all because it came off during the first windstorm, but I was able to get it to stick better the second time around by making little long tape loops out of 2″ wide bifilament tape, sticky side out, to stick the sticky side of the magnet tape to the bifilament and stick the bifilament to the bubble wrap around the hole; that worked much better. On the door side I had the tape sticking out over the edge of the door with the magnet tape stuck to the sticky inside of the tape, making a little magnet flap. You have to be careful to stick the magnet tape together first so it’ll be lined up, then tape everything down with the door closed so it’s all perfect.

The door in its final form. See if you can zoom in a little.

Oh yeah — I picked up a small roll of that whiteboard tape stuff and a couple of thin dry-erase markers and made a little message board, which actually got put to some good use. Whiteboard tape started peeling off after only a day or two, so I taped the edges with foil tape, and that worked great.

Assembly works like this:

Unfold tarp, marked side up. Put stuff on corners to prevent from blowing away. Pay attention to which way it’s oriented relative to the prevailing wind — I wanted the wind to blow into one of the arched sides, which I wanted to come down on the long sides of the tarp, not the short sides. Hammer eight straight rebar stakes straight through the tarp, just inside the thick reinforced part along the edges, near the 8 arrows marking where the ribs go. Each stake gets hammered in about halfway, so 1′ in the ground and 1′ sticking out. Same thing for the two Xes where the two vertical legs will go, near the centerline of the tarp. My tarp had a seam near there, so I put the hole just to one side of the thick part — it doesn’t need to be exactly right, the frame won’t be quite straight anyway, and you can cut the leg to the actual length, so it doesn’t matter. Make the stakes as straight as you can manage but don’t sweat it too much.

Grab two ribs and one pre-assembled rib connector. Insert taped end of each rib into connector, making a giant 20′ piece. Remember that there are two kinds of rib connectors, one kind for the middle and one for the ends. Slide one end of the 20′ piece into one of the straight rebar pieces, so it sticks straight up 20′ into the air. Grab with your hands as high as you can and start pulling it down towards the corresponding stake on the opposite side of the tarp, so that the long thin pipes bend into a 180 degree arc as you slide the other end onto the other stake. It should stay up there pretty good. Repeat for other ribs until you have four parallel arcs. Grab the three spine pieces and jam them in. Use three 4′ bungee cords wrapped around the rib connectors to hold the spine pieces in their connectors — in this design the roof might hold it in on its own, but I used the bungees anyway, can’t hurt.

Each end of each 4′ bungee loops around a rib and then hooks to itself.

The last piece of the skeleton is the vertical pieces. Grab the overly-long 10’x1.25″ pipes, put one end right next to the rebar sticking out of the tarp, put the other end next to the connector, see how high it is, add an extra inch or two of length so it won’t pop out, and use one of those little racheting PVC cutters to cut the pipe cleanly. (Avoid using a saw on the playa! Sawdust is MOOP!) Slide the cut end of the pipe over the rebar, then lift the whole frame a bit and slide the taped end into the connector. Maybe wrap some tape around the joint or something so it doesn’t come lose before you get the roof on. (Once you get the roof nailed down, this piece ain’t going nowhere.)

Now that the skeleton is complete, unroll and unfold the giant roof piece, get it flat, make sure the silver tape side is up, and drag it over the frame. Do not underestimate how tricky it is to do this, especially if there’s any wind. Get a friend or three to help, if you can. I used blue painter’s tape to tape it roughly to the ribs so it wouldn’t move around too much. Painter’s tape is nice because it’s easy to remove and reposition, but it isn’t strong at all, so watch out.

Unroll the two small wall pieces, get them as straight and as lined up as you can, and tape the vertical leg pipe to the middle of each piece. This is definitely a two-person job — one on the inside with the tape, one on the outside to hold up the wall and press where the tape is going — so be sure to grab a campmate or a random passer-by. I think I used 2″ bifilament for this right off the bat, but it might be better to start with painter’s tape and do bifilament once you’re sure it’s positioned right.

This photo only shows one point where the vertical support is taped to the wall, but I did this in three or four places on each vertical support. You don’t want to skimp on this, I promise.

Do the wood next. Get each piece of wood as close as possible to the frame before hammering in the candy cane stakes. For the roof piece, make sure its pulled as tight as possible. For the side pieces just try to make sure that they’re mostly straight and centered; you can pull them tight when taping the top. I skipped a few candy cane stakes, but I regretted it as soon as the first windstorm hit — the wall distorted noticeably, and after things had calmed down I wound up carefully yanking a foot or so of bubble wrap back under the wood with pliers and nailing down all the remaining holes. Was glad I had so much extra bubble wrap sticking out at the bottom, and that I hadn’t trimmed off the excess. With all the holes nailed down, though, I could have trimmed it if I’d wanted.

Get a stepstool or a camp chair or a box or something and go over the two outside seams, where the flat walls meet the arched roof. Use scissors to cut the two small pieces into rough semicircles, so that there’s at least a foot of extra bubble wrap sticking up past the roof, so there is plenty of overlap. Then use big pieces of bifilament tape going across the seam like sutures to secure it, then one or more long pieces of 3″ wide tape along the entire length of the seam to seal it up, then more crosswise pieces as needed to make sure everything is good and strong and isn’t going to come apart. Be generous with the crosswise pieces — I needed to extend them a foot or more on each side of the seam to get them to hold well. If there’s a loose bit of bubble wrap, don’t be afraid to just fold it over and put a big old piece of tape across it to hold it down and keep it tight. If you are feeling ambitious, you can cover the seam with silver tape, but I will admit that I didn’t bother to do this, and it was pretty okay. I had to add and/or replace a bit of bifilament tape midweek to keep things tight.

Another photo taken during disassembly. Confusing, I know. Anyway you can see how the wall is now trimmed into something more like a semicircle.

I waited until the structure was completely assembled before cutting windows, since I wanted them to wind up at just the right height so that a box fan sitting on one of my storage bins would line up with the window, and it’s a lot easier to figure out where that is once the structure is completely assembled, because otherwise you’d waste a lot of time during assembly trying to line everything up perfectly when in fact it doesn’t need to matter when all the wall and roof pieces are longer than they strictly need to be. Put a bin next to the center of a wall, hold up the filter where I want it to go, draw around it in sharpie, use scissors to cut three sides about an inch inside the lines. Because I want the holes to be a bit smaller than the filters, so it’ll be airtight. Fold the cut piece of wall back on the inside and tape it down — this way you can close it from the inside if you need to, like during a bad storm that rips the filter off. I didn’t need to, even in the worst of it, but it’s nice to have the option. Be sure to tape the filter to the outside of the structure, not the inside — you’ll get a lot less dust inside when changing the filters mid-week, plus it just fits better with the flap on the inside. I initially taped the filters down with 3″ wide hexayurt tape, but ended up retaping with 6″ wide tape, since I had some and it turns out it’s really hard to tape them down well without leaving holes or having things come undone when the wind tries to blow through.

Here’s what it looked like after it had been up for a week and a half, the day before I took it down. That window is on the windward side. See those big horizontal wrinkles? Those will let a ton of dust in under the tape unless you really tape the hell out of it.

Last part is the door! I wanted the door to be somewhat larger than the door-hole, so it would be easier to seal, so I left it off to make it easier to roll up the wall, and just lined it up and taped it on when I got there. I was willing to have my door start a few inches above the level of the ground and the piece of wood and so on, so I didn’t need to line up the wall piece super exactly, but if you are feeling picky about this it might be easier to save cutting the door for the playa so you can put it exactly where you want it after everything is nice and tight, like I did for the windows.

Teardown is pretty straightforward — same steps in roughly reverse order. Do try to keep things intact so you can reuse them, but if it comes to that it isn’t so hard to repair or replace any of this stuff. The bent rebar hooks are easy to pry out using a hammer or crowbar as a lever to get them started, but be careful not to bend them when pulling them out, as this makes it much more difficult to deal with them next time. For the straight pieces, I always use a pipe wrench to spin the rebar around in-place, then grab it with the wrench or with my well-gloved hands and yank it straight out. (Don’t even think about ever touching rebar without gloves, it’s unbelievably sharp and oily and heavy and rusty and horrible. Sorry, should have mentioned that earlier.) If a few spins don’t loosen it up enough, try pouring a bit of water into the top of the hole and spinning it some more to work the water down and loosen things up. Or you can get one of those fancy giant stake-pulling tools, but that almost seems like cheating, doesn’t it? Which is to say that you should totally pick up one of those if you have the funds and the space for it, you’ll be really popular I guarantee.

Some things I enjoyed about this design:

It was warm at night, and cool in the morning, so I could sleep in! Maybe not so cool during the hottest part of the day, but even that was totally bearable when I put the fan on. (Brought the fan, battery, and RGB LED strip from last year, skipped the solar panel, had no trouble getting through 12 days or however long I was there.) Temperature difference between inside and outside was comparable to last year’s hexayurt with its 1.5″ thick foam walls, which is to say that it varied between zero and maybe ten or fifteen degrees in either direction depending on the time of day.

Indoors about 12 degrees F warmer than outdoors a few minutes after midnight on the morning of 2015-09-05. This is soon after I got back, from ground heat, not my body heat.

Unlike the hexayurt, I was able to fit this thing inside my car rather than having to strap it to the roof. I was able to load and unload it on my own, rather than having to have a huge production with lots of people and stepladders and dropping things and damaging the car and pulling over to re-tighten and wondering if it was going to fly off and kill somebody. Even the big roof/wall piece is easy for me to grab and move around when it’s rolled up into a cylinder. I was also able to do almost all of the assembly on my own, which again would have been just unthinkable with the hexayurt. If it had come to that, I think I would have been able to fake my way through everything even if I’d been alone in the desert, assuming not too much wind anyway. Honestly this isn’t so much of a big deal on-playa where there are always friendly people willing to help, but it can be a big deal before and after the event.

The floor area for this design is something on the order of 140 square feet, vs about 166 for an H12 or similar hexayurt. The floor plan is much nicer, though — it’s a square, not a hexagon, so it’s easy to fit square things like mattresses and boxes. And the walls are steep enough and the roof tall enough that I felt like I could stand up almost everywhere, despite being a bit on the tall side as humans go, as opposed to the yurt where I felt like I had to crouch down a bit almost everywhere. It basically doesn’t get any better than this. 140 square feet is super luxurious for one person, which is how I like it. It would be very easy to fit several people, and it’s easy to imagine lengthening the tube for even more space.

It’s super easy to do on-playa repairs and customization! Tape sticks really well to the bubble wrap. Tape sticks well to foil-laminated foam hexayurt panels too, but the foil rips right off and exposes crumbly fiberglass foam that makes a mess and is hard on your hands and is bad for the playa. Which is also why you don’t want to ever cut foam panels on playa. Cutting bubble wrap is super easy with regular scissors and makes no mess. A related point is that it’s fricking impossible to reach the top of the roof cone of any but the tiniest hexayurt, even with a tall ladder, because it’s way out in the middle there, whereas with this design it’s very easy to reach just about any part of the structure that you might ever need to reach with nothing more than a small improvised stool or chair; in particular the outside seams that need taping on-playa are right there on the ends.

I stuck one of those remote-controlled RGB LED strips to the inside of one of the ribs.

Both this design and the hexayurt look pretty cool and shiny and nifty and all that. But nowdays you can’t spit at Burning Man without hitting a hexayurt. Maybe someday this design will also be commonplace? Anyway I got a lot of curious and appreciative comments.

Both designs seem quite sturdy. I may have mentioned that there was a lot of wind this year — at least two major windstorms that destroyed a bunch of things; I’m going to be very conservative and guess that both had frequent gusts that exceeded 30 MPH, though the one dude with the anemometer claimed a fair bit more than that because of course he did. I think the major risk to both types of structure might be from other large things blowing around and colliding with the structure — saw a couple hexayurts severely damaged in this way this year — which is another reason being able to make repairs easily is important to me. (Those hexayurts were repaired, but only because we were a huge camp with multiple spare foam panels just lying around and enough people to have six people holding up each roof corner and more people on the inside and outside lining up and taping the new wall panels. It was ridiculous.)

An insufficiently secured shade structure in a neighboring camp blew into this poor innocent hexayurt.

We got a bit of rain last year, and my hexayurt was not waterproof, and I decided that it probably would have been almost impossible to waterproof it (too many little wrinkles where the water can seep under tape), and I think the same is likely true of this structure. At this point, waterproofing is a non-goal for me — it’s easier to keep my stuff in bins and bags and sleep on a raised air mattress. Like the hexayurt, this design seems likely to let water run down the walls rather than dripping annoyingly from the ceiling, but I guess I can’t say for sure.

I think the best thing for me, though, was that I got to try something new, and it worked out. I had a lot of fun thinking about this and putting it together. I went through so many different ideas. It really kept me entertained!

We’ll see what happens next year….